ISO-CONNECT VARIO XD

|

|||||||

Product description |

Product advantages |

||

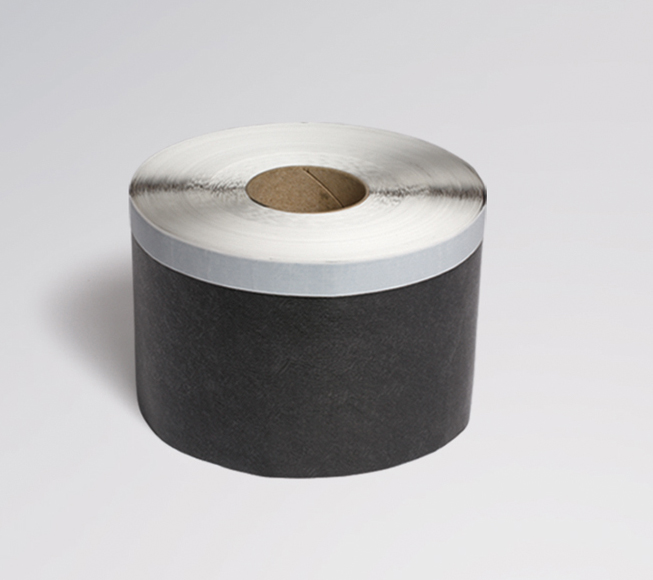

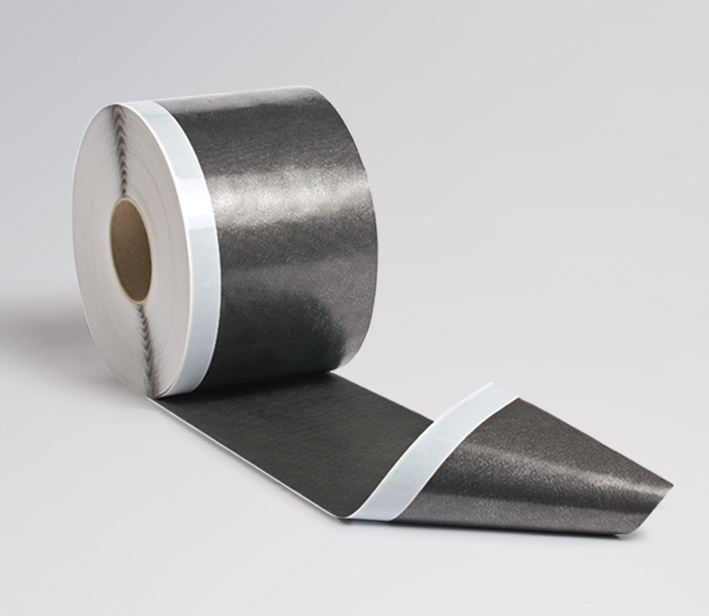

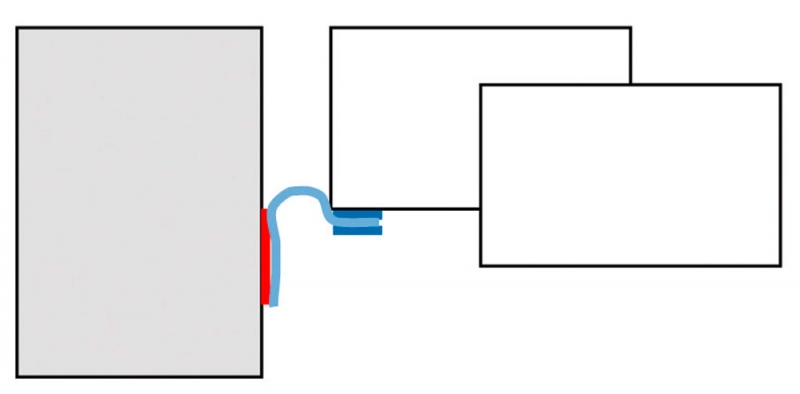

| ISO-CONNECT VARIO XD is a humidity variable special foil for the inner and outer sealing of windows and facade connecting joints. The foil reacts to the different seasonal temperature gradients by variably adapting its sd-value,thus achieving a high drying effect in the joint all year round. It complies with the requirements of EnEV (energy saving regulations) concerning to the airtightness of the building envelope and the recommendations of the RAL quality assurance association for windows and doors in the “Installation guide”. |

|

||

Application |

|||

| ISO-CONNECT VARIO XD is excellently suited for the sealing of both internal and external window and door elements in metal, window and facade constructions. The fleece-covered special foil is available in different self-adhesive finishes for quick and proficient installation. The foil can be used under the window sill (eg. for External Wall Insulation systems) as the 2nd trough shaped sealing level. |

| Technical data | Standard | Classification |

| Material description | polymer fleece foil | |

| Colour | black | |

| Building material class | DIN EN 13501-1 | E |

| Impermeable to driving rain | DIN EN 1027 | ≥ 1050 Pa |

| sd-value (vapour diffusion permeability) | DIN EN ISO 12572 | Depending on the average air humidity, sd-value between approximately 1 m and 12 m** |

| Air permeability coefficient | DIN EN 12114 | a ≤ 0,1 m³/[h*m*(daPa)ⁿ] |

| UV light stability (fleece side) | approximately 12 months | |

| Temperature stability range | approximately -40°C to +80°C | |

| Handling temperature | approximately +5°C to +45°C | |

| Dimension tolerance | DIN 7715 T5 P3 | requirements fulfilled |

| Shelf life | 1 year, dry and in original packing |

|

** The recording of the variable sd-value is only possible with a dynamic calculation program (e.g. in accordance with literature specification [10] in DIN 4108-3:2001-07). When calculation is done using a static method, a fixed sd-value of 2.5 m can be used. |

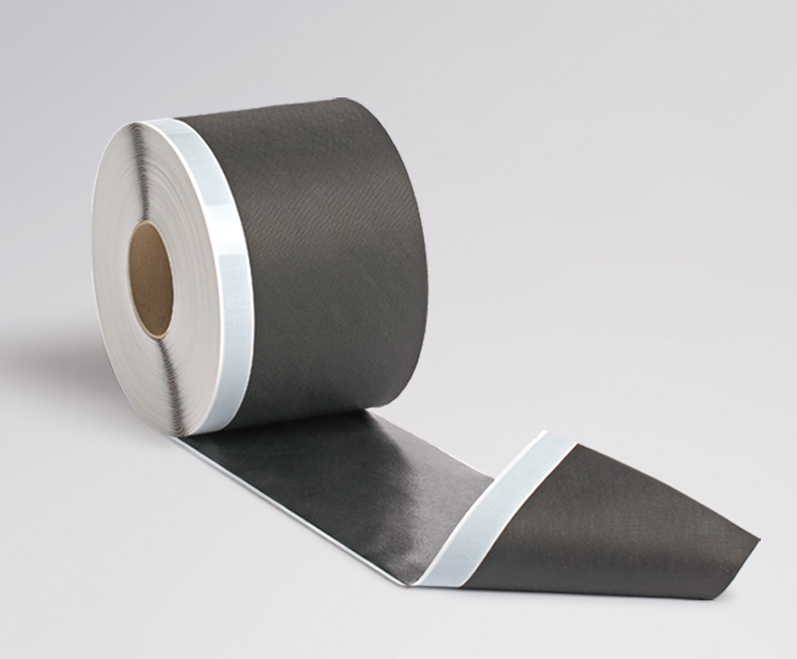

Processing |

Select specific version according to installation details |

|||

|

The bonding surfaces must be free of humidity, dust, stripping agents, oil, grease and other anti-adhesive substances. Pre-treat porous and absorbent surfaces with primer. Bond the window connection foil without tension with sufficient slack for movement between the frame and the building reveal. Unless using Finish F, we recommend ISO-TOP FLEX-ADHESIVE for this purpose. Apply enough adhesive to leave a caterpillar strip about 30 mm wide and at least 1 mm thick after the foil has been pressed in place. With the butyl self-adhesive version, pre-treat the surface with primer if necessary and then apply the butyl self- adhesive to the surface. Use a roller to carefully press the strip in place. On areas which are to be plastered over, a full surface bonding caterpillar strip should be applied. A foil surface of max. 20 mm should be left unglued to allow for potential movement. Corners and overlaps in the foil must be bonded using ISO-TOP FLEX-ADHESIVE. Fully self-adhesive finish COMPLETE does not require any additional adhesion with our ISO-TOP FLEX ADHESIVE. It must be noted that only the fleece-covered side can be plastered over. The window connection foil bonded to the outside of the building must always be covered. As the 2nd level sealing, under a window sill, lay it in a trough shape with side going up the reveal wall, paying particular attention to the corners (possibly with preprepared corners) and stick with ISO-TOP FLEX-ADHESIVE. For detailed information about processing see the installation instructions. |

||||

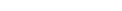

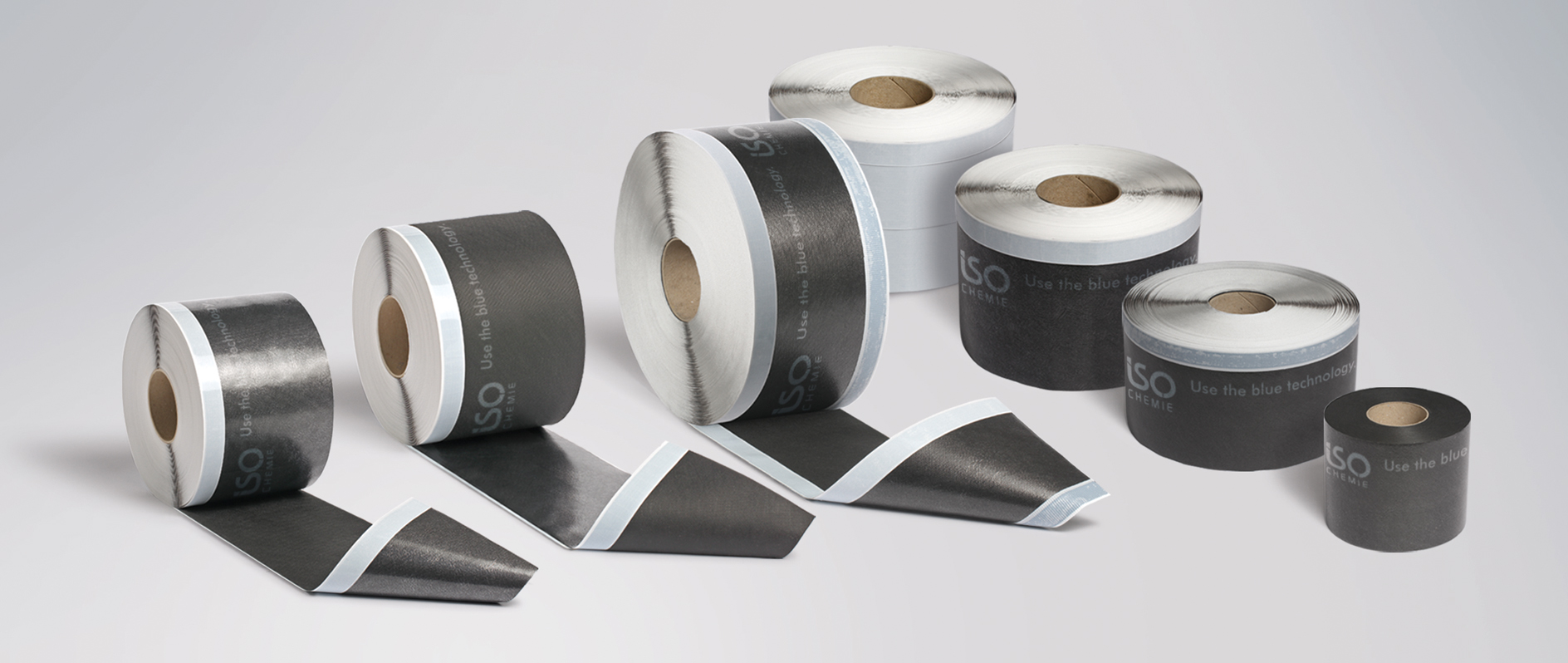

Dimensions |

||||

| Width: 70 – 600 mm (depending on the finish) | ||||

Packaging |

||||

| In rolls, roll length: 50 m (finishes A, B, C, D, E and F), 30 m (finish COMPLETE) | ||||

| Product Data Sheet |