Preparation

|

|

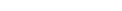

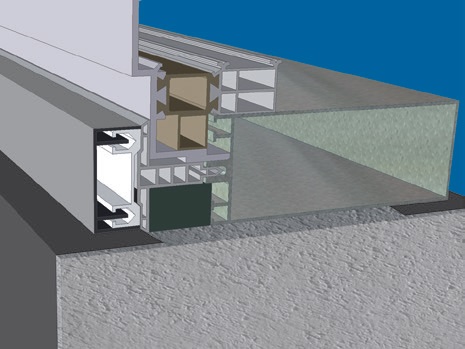

Installation example

ISO-CONNECT EPDM SEALING CORNERS

|

| To supplement ISO-CONNECT OUTSIDE EPDM, we also supply moulded EPDM sealing corners for various connection areas on buildings. These can be used for in front of wall elements, for the lower connection area, on floor-level elements, balcony doors and patio door systems. For further information, see datasheet of ISO-CONNECT EPDM SEALING COLLAR AND SEALING CORNER. |

DIMENSIONS SEALING CORNERS

|

| inside corner: 100x100x100 mm (thickness 0,75 and 1,2mm) |

| outside corner: 200x200x100 mm (thickness 0,75 and 1,2mm) |

|

|

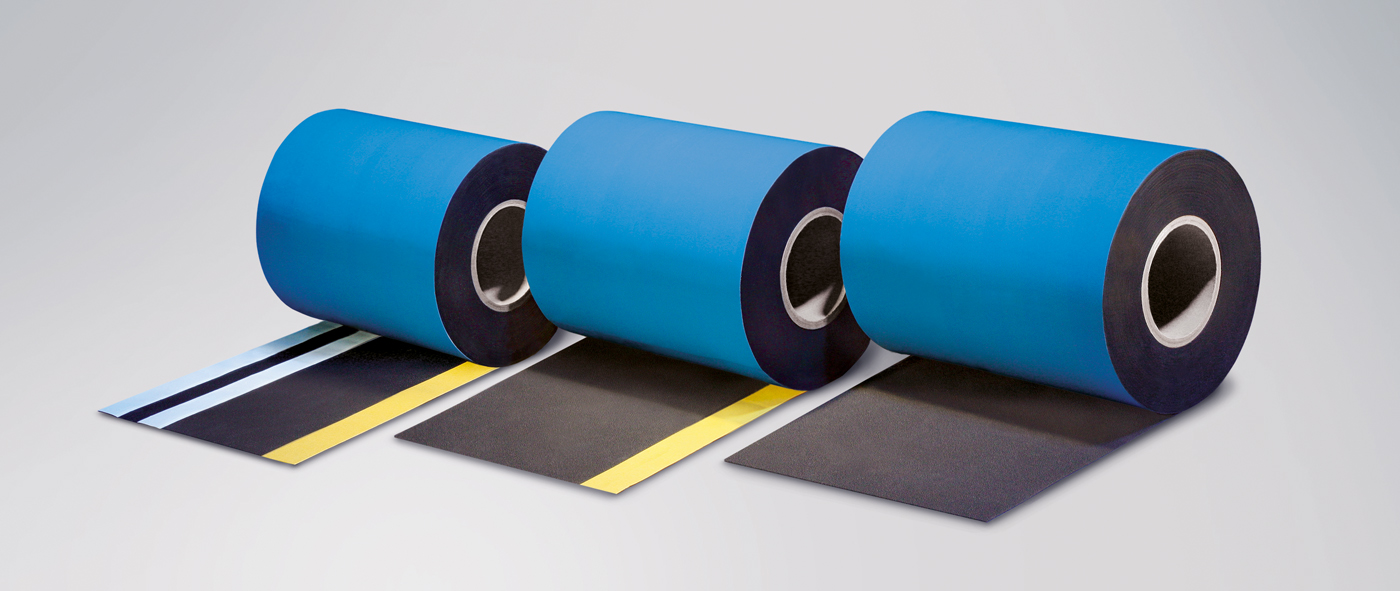

Unroll ISO-CONNECT OUTSIDE EPDM elastomer sealing band and cut to the required length. The surface must be clean, dry and free from solvents, grease, dust, oil and other anti-adhesive substances.

|

|

|

To generate an airtight seal, bond one edge of the band with a gunable solvent free adhesive such as ISO-TOP FLEX-ADHESIVE XP and fix the other edge with mechanical fixings, e.g. clamps or components of the window system as described in DIN 18531 and DIN 18533. Alternatively, versions B and D are supplied with an acrylic adhesive strip to assist attaching the end to the aluminium window until the mechanical fixings are installed, or a gunned adhesive is applied. When using versions with Butyl adhesive, pre-treat any porous and absorbent surfaces with ISO-TOP BLUE PRIMER and then apply the self-adhesive material to the surface. For all adhesive areas use a roller to carefully apply pressure to the area until the product adopts the contours of the facade.

Butyl caoutchouc adhesives are sensitive to solvents. When bonding the complete surface, using a solvent based contact adhesive, coat both the band and the substrate and then carefully press into place.

|

|