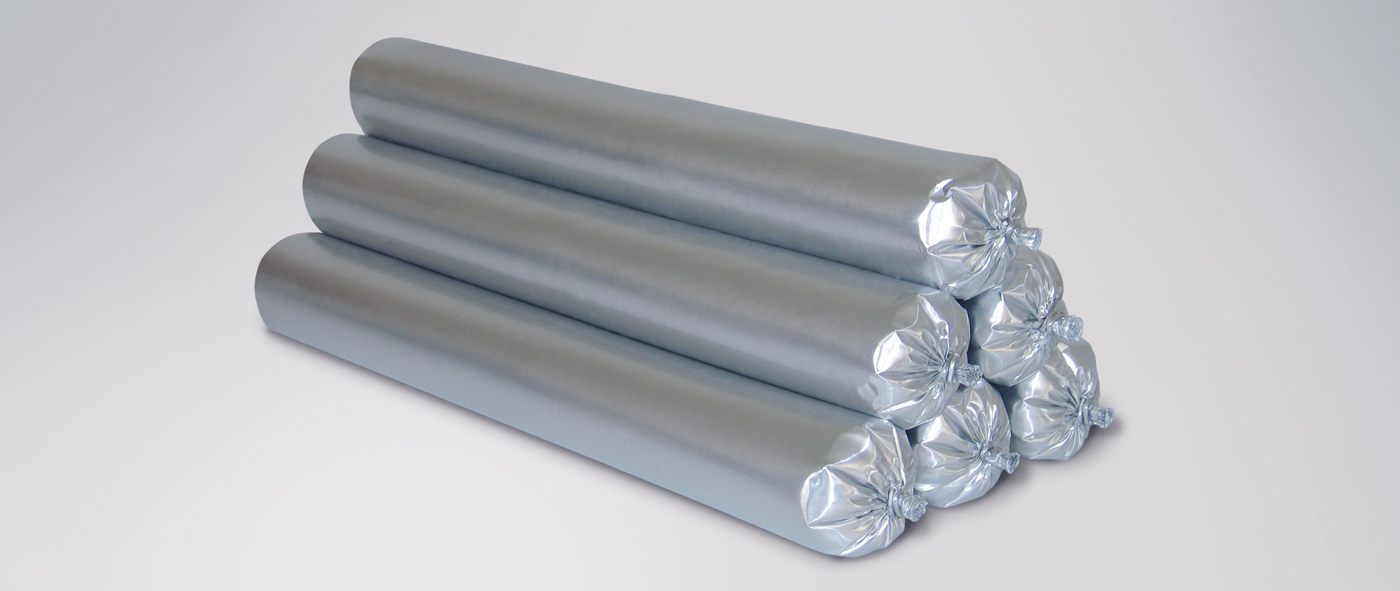

ISO-TOP FLEX-ADHESIVE

Product description |

Product advantages |

|

|

ISO-TOP FLEX-ADHESIVES are high quality sealants and adhesives, with a wide adhesive spectrum. |

|

|

Applications |

||

|

They are suitable, in accordance to DIN 4108-7, for a reliable, air-impermeable bonding on window connect- ions foils. ISO-TOP FLEX-ADHESIVES are specially designed reliable bonding agents for window connections foils, fleece and paper in building constructions, providing an air-impermeable connection to masonry work. |

||

Service |

||

|

Packaging |

||

|

|

| Technical data | ||||

| ISO-TOP FLEX-ADHESIVE | XP | SP | SP+ | PA |

| Material description | soft elastic special polymer | |||

| Colour | black | white | grey | light blue |

| Base | MS polymer, solvent- and fungicide-free | 1-K-acrylate dispersion, solvent- and fungicide-free | modified spetsial polymer, solvent, fungicide-free | acrylate dispersion |

| Consistence | paste | |||

| Density | 1,5 g/ml | 1,7 g/ml | 1,4 g/ml | 1,2 g/ml |

| Handling temperature: ambient temperature bonding surface temperature | +0°C to +40°C +0°C to +35°C | +5°C to +40°C +5°C to +35°C | -5°C to +40°C -5°C to +40°C | +5°C to +40°C +5°C to +40°C |

| Curing process | polymerisation through humidity at room temperature | physical drying | absorption of humidity; at temperatures below +5 °C curing is delayed | physical drying |

| Temperature stability | -40°C to +90°C | -20°C to +80°C | -30°C to +80°C | -40°C to +100°C |

| Skin forming | approximately 10 min | approximately 20 min | approximately 15 min | permanently sticky |

| Curing speed* | approximately 2 mm / 24 h | approximately 2 mm / 24 h | approximately 2 mm / 24 h | |

| Coverage | depending on surface structure and a bead of 8 mm x 8 mm, approx. 10 m | 8 mm beed approximately 6 m. | ||

| Building material class (DIN 4102-1) | B2 | |||

| Building material class DIN EN 13501 | E | |||

| Shelf life | up to 12 months, in a cool and dry place, in original packing | up to 12 months, in a cool and dry place, in original packing | up to 9 months, in a cool and dry place, in original packing | up to 24 months, in a cool and dry place, in original packing |

| Storage temperature | +5°C to +25°C | +5°C to +25°C | +5°C to +25°C | +5°C to +40°C |

| Especially suitable for | ISO-CONNECT OUTSIDE & INSIDE CX, OUTSIDE & INSIDE FD, OUTSIDE & INSIDE EPDM, VARIO SD & VARIO XD (fleece side); ISO-BLOCO ONE (corner bonding), 300 ja 600 (additional sealing) | ISO-CONNECT OUTSIDE & INSIDE CX, OUTSIDE & INSIDE FD, VARIO XD (fleece side), restricted REVEALSEAL | ISO-CONNECT OUTSIDE & INSIDE CX, OUTSIDE & INSIDE FD, Vario SD, Vario XD (fleece side) | ISO-CONNECT OUTSIDE & INSIDE CX, OUTSIDE & INSIDE FD, VARIO SD & VARIO XD, INSIDE EPDM perimeter area; ISO-BLOCO (corner bonding) ONE & RENO & ONE CONTROL |

| * Measured in accordance with DIN EN ISO 291 standard climate at 23 °C / 50% RH, values can vary through environmental factors (temperature, moisture, surface). | ||

Processing |

||

| The application surface must be stable, firm, free of dust, cleaning agents, oil and fat. Fill out large surface voids in advance. Normal surface irregularities can be compensated for by adding sufficient adhesive. Porous surfaces can, if necessary, be pre-treated with ISO-TOP PRIMER. Apply bead of 8 to 10 mm on to the surface. Apply the foil, fleece, paperboard or paper without tension; meaning with a loop on to the freshly (no build up of skin) applied adhesive bead and press down lightly with appropriate tools. When installing window foil sealants apply sufficient ISO-TOP FLEX-ADHESIVE to assure that after the window foil has been pressed into place the width of the adhesive is at least 30 mm wide and at least 1 mm thick. |

According to related standards (e.g. DIN 18540) elastic sealants should not be completely painted over, as tension and movement in the non-elastic paint may occur and could cause cracking. It is advisable to do a preliminary bonding and compatibility test on all surfaces. |

|

Work Safety |

||

|

Please refer to our EC safety data sheets for hazards, safety tips and storage, disposal and transportation markings. |

||

| Product Data Sheet | ||